Introduction: Willoughby Smith had a long and distinguished career in the early cable industry, from its beginnings in the late 1840s until his retirement in the 1880s. In 1891, shortly before his death, his book “The Rise and Extension of Submarine Telegraphy” was published. This page reproduces the first two chapters of the book, in which Smith describes the manufacture and laying of the first ocean cables ever made.

The illustrations shown here did not appear in the original but are are added from contemporary sources; links to other parts of the site provide further background information.

|

| Landing points of the 1850 and 1851 cables |

|

View Dover-Calais in a larger map

|

|

Chapter I

Willoughby Smith |

Early in 1850 the Gutta Percha Company received what they then considered a very large order. It was for twenty-five knots or nautical miles (2,029 yards representing a knot) of copper wire, No. 14 Birmingham wire gauge, to be covered with gutta percha to half an inch in diameter. Great care was to be exercised in the covering of this wire, which was required for laying across the Channel from Dover to France, to prove, if possible, the practicability of submarine telegraphy, and universal interest was taken in what was characterized as a bold and daring experiment. Unfortunately, many things were at that time thought perfect which would not now pass muster; for example, the wire-drawers of those days, strangers to long lengths and proper annealing, appeared to take it for granted that the Birmingham wire gauge was any size they chose to make it; the result being that the diameter of the wire varied considerably, even when supplied by one firm. To its electrical conditions and quality no attention was given, for the simple reason that all copper wire was credited with the possession of equal value in these respects.

The Gutta Percha Company could only cover short lengths of the wire at one time, and even then were not able to insure its being kept in the centre. The method of cleansing the gutta percha, too, was very defective, and also there were, to contend with, many air holes and other imperfections, caused by the application of the gutta percha so thickly in one covering. The wire was supplied in short and variable lengths, which, to suit the requirements of the covering machine, had to be joined by overlapping scarves soldered together with hard solder by the aid of powdered resin and blow-pipe, the whole being filed to the size of the wire.

With the covered wire this process did not answer, as, owing to the amount of heat required to melt the solder, the wire became so hot as to soften the gutta percha for a considerable distance on either side of the joint; other methods for making the joints were therefore discussed, and the plan eventually adopted was as follows:—

The gutta percha was removed for about two inches from either end of the wires, which were then well cleaned with emery paper, crossed and twisted several times one over the other, bell hanger fashion, and the whole covered with soft solder applied with an ordinary soldering iron, common powdered resin being used as a flux. A suitable slice of plastic gutta percha was then placed on either side of the joint, the whole pressed in a wooden mould, where it was kept under pressure until the gutta percha was quite hard. The joint thus made resembled, when removed from the mould, a magnified cigar, some two inches in diameter and nine in length; it tapered at either end to the size of the covered wire over which it lapped. Each coil of wire was immersed in water as soon as covered, and, if thought sufficiently insulated, passed. The electrical arrangements were not elaborate, and although the battery generally used looked formidable, it was totally unsuited to much of the work for which it was required. This battery consisted of a long and narrow wooden box, divided by wooden partitions into twelve cells; at either end of the box was a fixed wing-head terminal, the one firmly secured to a zinc, the other to a copper plate; similar plates of zinc and copper were riveted together by bands of copper, and so bent over the wooden partition that each cell contained two plates of dissimilar metal immersed in a mixture of water and sulphuric acid; for better insulation, each cell was lined with an insulating compound. The box was covered with a hinged lid, the two ends of the terminals being left easy of access for the desired connections. The galvanometer used was of the vertical needle form and not very sensitive, the record being given as the number of degrees to which the needle was deflected with one cell; if under these conditions there was unsteadiness of the needle or too many degrees deflection, the coil was again examined and re-tested until it passed. Mr. William Reid, engaged as engineer and electrician on this occasion, and responsible for the electrical condition and the laying of the line, was a celebrity in his time, and held responsible positions from the commencement of electric telegraphy until his death.

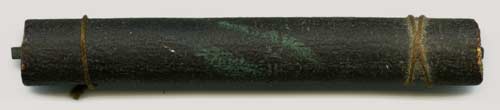

The 1850 cable (section recovered in 1854) |

When the Gutta Percha Company had completed the covering of the 25 knots of wire, reports were circulated to the effect that the enterprise was hampered by financial difficulties. Whether report in this case told the truth or not, the fact remains that the many coils which constituted the entire length were for weeks stacked in the yard of the Gutta Percha Company’s Works without adequate protection either from the depredations of the curious or the uncertainties of the weather. Eventually the coils were carted to a wharf on the Thames, whence they were shipped on board the small steam tug Goliath, and taken to Dover harbour. Just abaft the funnel of this tug a large iron reel was mounted on suitable bearings; its ends nearly reached the bulwarks on either side. Upon this reel the twenty-five knots of covered wire were to be wound as evenly as possible. As the coils had been so long out of water, it was thought advisable to re-test before joining them into one length; for this purpose, a batch of coils was suspended daily over the side of the tug in the water, the ends of each coil being secured just above the side of the vessel and made ready for testing.

The testing was done by Mr. Reid, who, seated astride a beam of timber on deck with his vertical galvanometer before him, shouted “Right” or “Chalk” as the case might be; “Right” denoting that the coil was passed, “Chalk” that the line-man was thus to mark the coil, to show that its electrical condition was such as to require re-examination. While this was going on, men were employed in joining the perfect coils and winding them on the iron reel, a very slow process, as the wire had to be wound as evenly as possible—a difficult task, owing to the size of the joints and other causes. Cotton waste was used, where possible, to fill up the inequalities; wooden laths also, when necessary, were placed lengthwise at equal intervals round the reel, the wire being wound over them. From lack of room on the tug, the rejected coils had to be re-examined on the quay, a proceeding attended with much annoyance, because crowds of people daily assembled to watch the process and freely criticise what they saw, in no very flattering terms; of course they imagined they understood all about it, and talked at the operators. “What a mad scheme! why a sailor, or anyone who knew anything about seafaring matters, would declare it was impossible to pull such a line 25 yards, let alone that number of miles, over such a rough and uneven surface as the bottom of the channel had.” These wise persons were clearly of opinion that the signals were to be made with France by pulling the wire after the fashion of mechanical house bells! However, one quiet-looking old gentleman seemed to take a more optimistic view of the case, for he remarked, “Why when they said that the railway was coming to Dover through Shakespeare’s Cliff, there were many with a knowing shake of the head and laugh of derision; but it was accomplished for all that, and these men will be equally successful, mad though some people think them.” Some of the spectators had the impertinence to cut through the gutta percha to show their friends that there was copper wire inside, while others still less scrupulous purloined a piece of the line when they thought there was a chance of doing so without detection.

The tug went several times over the course to Cape Grisnez, as though an attempt were being made to get her used to the route on which she would eventually play such an important part. On one of these visits, the shore end of the cable was laid from the lighthouse at Cape Grisnez in a prepared trench to the edge of the cliff; here it hung over; from the foot of the cliff it was laid among the rocks and taken for some distance out to sea, where the end was buoyed. The shore end consisted of a copper wire doubly covered with cotton, overlaid with a coating of india-rubber, the whole being enclosed in a very thick lead tube; the india-rubber, at the time of laying, was in a semi-fluid state from partial decomposition.

The cable being taken up the cliffs at Cap Gris Nez |

Cape Grisnez is high and rocky, with huge boulders at its base; at high water these rocks are in many cases hidden, the rise and fall of the tide from maximum to minimum being very great. Between the rocks there are several sandy bays in which a boat can be landed, but it requires an intimate knowledge of the coast to find the way to them, especially at certain states of tide.

All communication between the shore and the tug had to be made in the steamer’s boat. When the shore end was to be landed, the boat, being heavily laden with the reels containing it besides several passengers, took the bottom sooner than was expected. The sea at the time was very rough, and the majestic billows breaking on the beach seized the little boat as their plaything. The young and agile jumped at once into the water, so as to lighten the boat, and at last, after much difficulty, all reached the beach in safety without further mishap than a thorough wetting.

A shore end, precisely similar to the one at Cape Grisnez, was laid from a horse-box in the yard of the railway station at Dover, across the road, along the wooden stage erected to assist in the building of the Admiralty Pier, then just commenced, and into the sea, where it was buoyed. The correspondent of the local paper must have grown tired of reporting the very slow proceedings, as at last he simply gave us a note, such as “The Goliath took her usual preliminary trip over the course between Dover and Cape Grisnez. Among the scientific men on board we noticed Captain Beer.” The gentleman referred to happened to be the captain of the tug. When everything was considered ready for the “extravagant project,” a trial trip was made in a rather rough sea off Dover, by laying about three miles of the line. This was satisfactorily recovered, the tug returning to make final arrangements before commencing to lay the whole length to Cape Grisnez.

Temporary station at Dover. Vessels preparing to set sail. |

At last the eventful day arrived when this was to be, if possible, achieved, and at about 10 a.m. on August 23rd, 1850, the weather proving so propitious that one might imagine all Nature approved of the undertaking, the joint was made from a boat between the sea end of Dover shore terminus and the wire on the reel on board the tug. This accomplished, H.M. surveying paddle-ship Widgeon led the way, followed by the Goliath, from which the line was being paid out. The deck between the reel and the taffrail was kept clear, so that the line had a free passage from the reel into the sea. While Messrs. Reid, sen. and jun., Wollaston, jun., and myself were busy with the work in hand, on the deck might be observed a small group of spectators, Messrs. T.R. Crampton, John and Jacob Brett, Wollaston, sen., and Edwards. Whilst the cable slowly unwound the onlookers passed the time in discussing the topics of the day; they spoke of H.R.H. Prince Albert, his extraordinary scientific attainments, and the great interest he was taking in our proceedings; of the death of Louis Philippe, and the effect his demise would exercise upon the destinies of France.

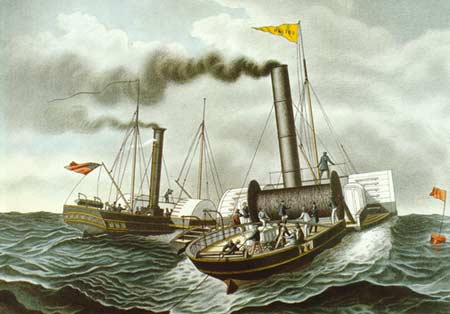

Goliath paying out the cable, accompanied by Widgeon |

The specific gravity of the line was so little below that of the sea water that it was thought advisable to attach leaden weights, a sixteenth of a knot apart, to ensure the line being taken to the bottom. These weights varied from 8 to 16 lbs.; they were flat square shaped blocks cast in two halves; on one half were two projecting studs, and through the other two holes to receive the studs; along the centre of each half was a semi-circular groove corresponding to the diameter of the line. To attach these weights, strips of plastic gutta percha were laid in each groove and the halves pressed together; the two studs which projected through the two holes were hammered flat by two men, one on either side of the line. It was at first thought that the men could attach the weights while the line was passing from the reel to the taffrail, but experience proved otherwise, as in their hurry to do so they more often struck each other than the studs; it was therefore deemed expedient to stop the paying out while this operation was being performed. The line must in consequence have been very taut in those places, and it is a wonder how the gutta percha stood the tension and knocking about it received. The Widgeon took soundings, communicating the result to the tug by means of large chalk figures on a black board placed on the paddle-box, and the large or small weights were used according to the soundings given. Mr. F.C. Webb, an officer of the Widgeon, was on board the Goliath to interpret the signals from the pilot ship. Unforeseen difficulties now presented themselves; not only did the cotton waste used in the reeling of the line fly in all directions, but the partially released wooden laths behaved after the fashion of flails in the hands of infuriated threshers, making it extremely dangerous for anyone to approach the reel until the laths became totally released.

During the laying no messages were sent or received, only electrical signals on galvanometers were exchanged as opportunity offered.

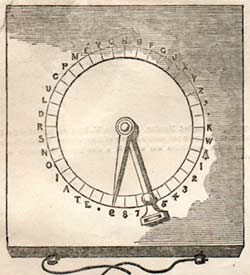

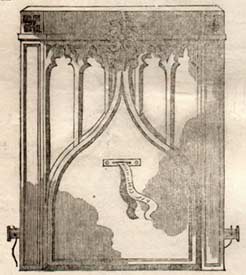

At about 5 p.m. on that memorable day the tug had accomplished her allotted task, and anchored in the vicinity of the shore end buoy off Cape Grisnez. The sea end of the line was then passed into the cabin of the tug, where it was connected with one of Brett and Little’s modifications of the “House Roman” type-printing instrument. But what had gone wrong with the operator at Dover? True, letters came, but they were so mixed that it was in many cases impossible to make any sense out of them. The man in charge of the instrument was justly rebuked for destroying them; they were the first messages received by submarine telegraphy, and as such ought to have been preserved, no matter how illegible. The more the operator tried to control the letters the more erratic they became. At last it was suggested that the success attending the laying of the wire had caused the champagne to circulate so freely that the persons in the shore station at Dover did not know what they were doing. This solution of the mystery really did appear to be a feasible one, more especially as the man in charge of the type-printer showed how correctly he could work it on short circuit.

To save daylight for making the final splice and getting to the shore, the end of the line was passed into the boat, where it was joined to the shore end: thus was submarine telegraphy presumably established between England and France. The steamer then left, and those interested ascended to the lighthouse, where an ordinary single needle instrument was attached to the line; but although messages appeared to be sent correctly, and Dover gave what was thought to be the signal of acknowledgment, no other message came. This merely confirmed the champagne theory. The only thing to be done, therefore, was to wait until morning, when all would doubtless be explained. As it was now 12 p.m. the company separated; some walked to Calais, while others preferred to forego their supper and seek what rest a lighthouse could afford.

The Communicator or Dial Plate |

|

Printing Apparatus |

In the morning all were astonished to find the results on the single needle instrument the same as before; the type-printer was not tried. It was now decided to await patiently the arrival of the mail from England. In due course letters reached us containing the astounding statement that at Dover the signals received had been very similar and in the same chaotic order as those complained of at Cape Grisnez. To add insult to injury, came the suggestion that success had proved too much for the workers at our end, and caused carelessness and neglect; it was hoped, however, that business would now be attended to.

Had the phenomenon of induction been generally recognised in those days, and the true state of the line with regard to its electrical condition understood, what an amount of misunderstanding and mutual recrimination would have been avoided. There can be no doubt that the continuity of the copper wire between Dover and the tug anchored off Cape Grisnez was perfect, and that it was owing to the retardation caused by induction that the letters were not received in the order sent; but when the Cape Grisnez shore end formed part of the circuit it is quite certain that continuity no longer existed, the supposed signal of acknowledgment being nothing more than the return current caused by the effect of induction.

It was evident to all concerned that something was wrong, and they had to grope about in the thick fog of ignorance in their endeavours to find the remedy, without even one ray from the important light of experience to illumine their path. It would be, therefore, not only unfair, but unjust, to criticise these endeavours by the light of the present day. Every device known and thought of was tried, but to no purpose; the line had at length to be abandoned. It is, however, a true axiom that failures are the best teachers, and this line had proved the practicability of submarine telegraphy, if only more perfect means could be obtained.

Whatever experiments may have gone before, I maintain that, in spite of its too brief working, the laying of the gutta percha covered wire from Dover to France in 1850 was the true pioneer of submarine telegraphy; therefore all honour is due to those engaged in it.

Below are shown illustrations of the joint and weight I have described, taken from originals still in my possession. It will be observed that they have somewhat deteriorated through age, more especially the joint.

Lead weight |

CHAPTER II

1851 cable |

After mature consideration it was decided that the next attempt, planned for the summer of the following year, should be made with a cable having four copper wires, each of No. 16 Birmingham wire gauge in diameter, covered separately with two coverings of gutta percha to No. 1 diameter of the same gauge, and twisted together in a similar way to the strands of an ordinary hemp rope. The interstices were to be filled up by tarred hemp strings, the whole being covered with similar strings wound round at right angles. This core, as it was termed, had ten galvanised iron wires, each of which was No. 1 Birmingham gauge, laid helically around it, so that it resembled in appearance a huge wire rope.

Those who supplied the copper wire were anxious to do their best, but still their wire was irregular in gauge and annealing, and in the same length would be found parts hard, brittle, soft, and rotten.

Insulating the copper wire with two instead of one covering of gutta percha and other improvements were no doubt steps in the right direction, but still the Gutta Percha Company had much to learn. The covering was very irregular, the lumps had to be spokeshaved before the wire would pass through the gauge which corresponded with the holes in the lay plate of the twisting or, as it was called, the core machine, and in some places the copper wire was more or less eccentric. Want of adhesion between the two coverings was also frequent, while “air-holes” and “gutters” caused much trouble.

The joints in the copper wire were made by scarfing the ends and holding them face to face by two small fixed upright vices, while hard solder by aid of the blow-pipe joined them, when cold the whole was filed to the diameter of the wire. Here again it was found that the heat required to melt the hard solder was too great for the covered wires, as it melted the gutta percha too far on both sides; very soft solder, which melted at a comparatively low temperature from a soldering iron, was therefore used. Two plastic bands of gutta percha, one after the other, were applied over the copper joint and manipulated by hand to the required diameter, a warm iron “tool” being used along the seam and at each end to amalgamate the whole.

The yarns used, both for covering and serving, were hard layed, and the composition of hot coal-tar and pitch with which they were saturated made them harder when cold; the knots in the yarns caused trouble, as they were hard lumps which pressed more or less into the gutta percha at the lay plate of the iron wire covering machine. The tension at the serving machine was not always uniform, as could be seen from the deep indentations made in the gutta percha by the hemp which was supposed to protect it. The iron wires were galvanised, but the process was badly done, large and dangerously sharp lumps of the metal adhering to the wire, and, in some places, cutting through the gutta percha, forming contact with the copper conductor. The welds were numerous and continually breaking while being reeled, or at the lay plate of the machine.

On one side of a somewhat narrow yard or court leading out of High Street, Wapping, in the direction farthest from the river Thames, were situated the Wire Rope Works of Messrs. Wilkinson and Weatherly; they may have been all that was required for their legitimate work, but for the manufacture of submarine telegraph cables a more inconvenient place as regards size and position could not have been selected. The core and covering machines were made and erected under the superintendence of Mr. Fenwick, an engineer of Gateshead, who also for a time had charge of their working.

The core was kept taut upon the drawing-off drum by manual labour, and, by the same means, was coiled in a number of small sections on the floor of an upper room, the completed cable being hauled to an open yard, where it was coiled and left exposed to the changes of an English climate.

Several miles of the core and a few knots of the cable had been manufactured when everything was suddenly stopped. “A silence that might be felt” held sway. Reports circulated that Messrs. Newall & Co., wire rope makers of Gateshead, had a patent for inserting a core of some soft material into wire ropes with a view to making them more pliable and more manageable; they therefore considered that this submarine telegraph cable was an infringement of their patent, and obtained an injunction to stop its manufacture. It did appear strange, especially to the initiated, that a submarine telegraph cable should be considered as belonging to the same category as a wire rope; true, in make and appearance they are the same, but for what different purposes are they required! By the same course of reasoning it would not be difficult to prove that a lightning conductor is a wire rope, and must therefore be a submarine cable; absurd logic doubtless, although in courts of law it might not be considered so. Whether the reports were correct or otherwise the Works were closed, and the gate of the yard guarded to prevent the entrance of strangers, more especially of Mr. Newall or any of his party; thus much valuable time was wasted on the road to success. At length Mr. Newall took possession and completed the cable with his own staff from Gateshead; as regards its electrical condition, more attention was given to the continuity of the conductor than to its insulation. The Government lent the hulk Blazer to carry the cable, but how to get it on board was the question, especially as the tenant of the property opposite had refused to endanger his fire insurance by allowing such a “Thunder and Lightning” thing to pass through his premises unless what was considered an exorbitant price was paid. Fortunately his neighbour was more reasonable, and the cable was, by manual labour, hauled from the yard of the manufactory to the Blazer, which was moored in the Thames. This was a long and tedious operation, the hauling having to be frequently stopped so that canvas and fine iron wire might be wrapped at right angles round the cable where a broken wire was detected. When at last the 25 knots of cable in one length were coiled into the Blazer, she was towed as close as possible to the beach beneath the South Foreland Lighthouse, where the end was landed and wires connected with the end, laid into a room in the lighthouse. In the hands of skilful operators messages passed through the cable between ship and shore by “double needle.”

On the morning of the 25th September, 1851, all appearing promising for the success of the expedition, it started, the Blazer being towed by two tugs, while a steamer lent by the Government led the way. The only means provided for retarding the egress of the cable was what was called a “Brake,” but it consisted of a simple wooden lever compresser worked by hand. As the day advanced the weather became what would be termed in sailor parlance “dirty,” the elements having to all appearance combined with the cable to try the strength of man’s endurance. What with the totally inadequate “brake” power, cable entangles caused by foul flakes, broken wires and tow ropes, the roaring wind and much agitated sea, a desperate struggle between mind and matter lasted nearly the whole of that memorable day. Want of sufficient cable caused the hulk to be stopped about one knot short of the desired landing-place, and so far matter had gained the day; but mind had not been conquered, only checked, for a knot more cable was at once ordered, and a makeshift arranged. Bare gutta percha covered copper wires twisted together had been laid in the ground from Sangette, where it was intended to land the cable, to the telegraph office in Calais, so a length of this subterranean line was joined to the cable and landed at Sangette, thus establishing electrical communication between the telegraph office in Calais and the South Foreland Lighthouse, and congratulatory messages freely passed to and fro between England and France.

The knot of new cable when completed was coiled on the after deck of the steam tug Red Rover, and she started in the following month for Sangette, but encountering very bad weather she eventually put into Ramsgate in a disabled condition. On re-starting all appeared to be going well until it was discovered that no person on board knew where Sangette was, consequently it was late in the day before the tug anchored off that place. The following day at high water the cable was laid as near to the shore as possible, and then parallel with it, and at low water horses were employed to haul it into position. The splice between the two cables was made on board H.M.S. Widgeon, which had been waiting for some days in Calais harbour for the tug, but owing to the erratic movements of that vessel had missed her.

The cable completed, subterranean wires were laid across the fields from the South Foreland to an ordinary dwelling-house in Dover, and it was decided to open for public service. On the morning of October 15th, however, to the general consternation, from some unknown cause the cable refused to work. It was at length discovered that one set of joints had been omitted in the subterranean line from the South Foreland, and this was the last link in the rather long chain of accidents and misfortunes which had obstructed the road to scientific success. Horsemen were employed to convey the messages to and from the telegraph office in Dover, and by the aid of the newly invented long distance electric fuse, a cannon at Calais was discharged by merely touching together two copper wires at Dover; Calais replying to Dover Castle in the same way. In fact, the day was one of rejoicing and congratulation, for a new branch had been successfully engrafted on the tree of knowledge.

|