The wires forming the outer sheathing of a submarine cable can, of course, only be laid on in two different directions, and, therefore, it would appear at first sight that very little misunderstanding could occur on the subject, yet, through a misunderstanding, half the first Atlantic Cable of 1857 was made with a lay reverse to the other half, thereby rendering it necessary to take certain precautions to prevent the cable untwisting at the central splice.

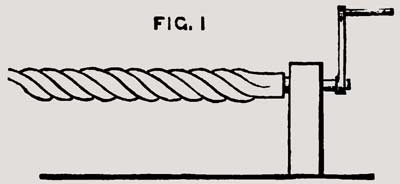

One lay is called “right hand” lay, and the other “left hand” lay, but on what authority, or why one should be termed “right” and the other “left “ the author has not been able to trace in any published record, although he has searched in most of the encyclopaedias and books of reference in which rope making is mentioned. He has heard two different reasons given:--The one that the “right hand” lay is that made by a man turning a simple rope-laying machine with his right hand; in which case, as he would stand with the rope on his right-hand side, and as a man generally turns a handle, pushing when the handle is at its greatest height, he would produce a rope as shown in Fig. 1.

|

Another reason given has been that this lay corresponds with the direction of what is called a right hand screw. The reverse lay is, on the same principle, calleda left hand lay.

It has been stated to the author, however, that everybody is not agreed even on this nomenclature, and if this is the case it is time that some attention should be drawn to the matter, for cables have been largely made to both lays, one manufacturer making in one direction, others in another, whilst some have made both lays. Even quite recently the author saw in the specimen case of a manufacturer the shore end and deep sea portion of two different cables in which the lay of the shore ends was reverse to the deep sea. It will be easily imagined that in sending from abroad for cable for repairs it is essential to specify the direction of the lay, as otherwise it is quite possible that spare cable may be ordered from some manufacturer who did not make the cable to be repaired, and who makes with a reverse lay to that of the manufacturer who made the cable for which the spare cable is required for repairing.

Indeed, no specification of a cable can be considered complete unless the lay of the wires is specified, not only for the immediate purpose of the specification but as a record, and to make sure that there shall be no misunderstanding it is better to sketch the lay on paper.

Yet no specification the author has seen contains this except some of his own.

In 1854 three cables were ordered for the Electric Telegraph Company for the Irish Channel, between Holyhead and Howth, and from the author’s experience on the Hague cables repairs he had found that it would be of great advantage to be able to identify the cables at sea when brought to the surface, as when cables are placed very near one another the position of the ship is not sufficient to identify them. Two of the Irish cables were, therefore, specified to be made of opposite lay, and the third to have a worming of an extra wire, and in an old letter copying book he finds the specification for the shore ends, which were made by Messrs. Glass and Elliot. It is dated Oct. 18, 1854. In this he had taken the precaution of specifying and drawing the lays thus:--

The cables to be of the following lengths and lay:—

1. One mile of left hand lay.

2. Three miles of ditto.

3. One mile of right hand lay.

4. Three miles of ditto.

5. One mile of left hand lay, with a No. 12 galvanised iron wire wound round outside.

Twelve miles of the left hand lay cable made for Ireland were afterwards used in June, 1857, to renew a portion of one of the Hague cables, which were right hand lay, and it was necessary to take precautions to prevent the cable untwisting at the splices.

At each splice the following plan was therefore adopted by the author. An iron plate, tapered from the middle each way, and grooved in its whole length to the radius of the cable, something like the fish piece to a boat’s yard, but with an iron arm projecting from its centre, carrying a weight, as shown in Fig. 3, was firmly lashed to each of the two splices.

|

Thus any tendency to untwist was counteracted by the weight. The same plan was adopted in the central splice of the Atlantic cable of 1858. The adoption of two different lays for the Irish cables, causing pieces of cable of different lay to be kept in stock at the Electric Telegraph Company’s Stores at Lowestoft, required that care should be taken to issue the proper cable for any particular repair. The term right hand and left hand was at first employed, but led to mistakes, and indeed it has in itself nothing to guide a person as to what it means without he previously knows and recollects the meaning any more than A and B, 1 and 2, or + and -. The author then adopted the following phraseology:—

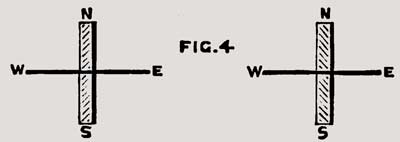

Let a piece of cable be placed with its axis vertically, and let it be supposed that its axis is a north and south line, then the direction of the wires seen will either run in a direction approaching north-east and south-west, or the reverse direction; that is to say, N.W. and S.E. Thus in one figure above the lay is N .W. and S.E., and in the other it is N.E. and S.W. Thus we have only to hold a piece of cable vertically to sec whether it is a N.W. lay or N.E. lay. And in using this mode of specifying the lay all we have to recollect is that the axis of the cable is the N. and S. line, and the names become N.E. for right hand lay and N.W. for left hand lay. But whether this plan of specifying, or the unmeaning one of right hand and left hand be adopted, it is certain that some care should be taken to specify the direction of the lay of every cable.

|

Of course, when a whole new cable for some new locality is ordered from a manufacturer it is not of so much importance for the moment what lay it is, but it is of importance to insert the lay in the specification for future reference, so as to know what to order for repairs. Most certainly, at any rate, when cable is ordered for repairs, the direction of the lay should be specified. Only recently an order came from New Zealand for open tender for a length of three-conductor cable for repairs. The papers of the last order had to be searched up to find who made the cable, and then the manufacturer had to be visited and asked as to the lay, when he said the lay must have been such and such a lay, although there were cables of different lays in his case. Indeed, it seems more by luck than anything else if some mistakes have not already occurred. The following are a few of the particulars of lays:-—

Right hand, or in the proposed phraseology, N.E. lay:

1. Most of Messrs. Newall and Co.’s cables.

2. The Direct United States deep sea cable-Atlantic cable.

Left hand, or in the proposed phraseology, N.W. lay:

1. Most of Messrs. Glass and Elliot and Telegraph Construction Company’s cables, including the 1865, 1866, 1869, 1873, and 1874 Atlantic cables.

2. The India Rubber, Gutta Percha, and Telegraph Works Company’s cables.