After the almost immediate failure of the 1850 Dover-Calais cable, its proprietors had only a limited time to establish a permanent line in order to comply with the terms of their franchise from the French Government.

Their next cable, laid in September 1851 from St. Margaret’s Bay, England to Sangatte, France (commonly referred to as the Dover to Calais cable), was the first-ever commercially successful undersea cable. A significant engineering achievement, it began a revolution in communications from which a line can be drawn directly to the hundreds of thousands of miles of fibre optic cable which carry almost all communications today.

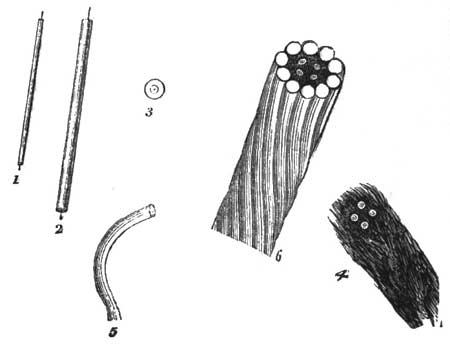

The design and construction of the 1851 cable established principles and methods which persisted for over a hundred years. An original factory sample of the cable is shown here, together with diagrams of its component parts.

|

|

Four 16-gauge conductors,

gutta percha insulation,

ten iron armouring wires with right-hand lay.

25 miles total length, weight 7 tons per mile |

The cable was manufactured at Millwall,

coiled on board HMS Blazer in September 1851, and laid under the direction

of Messrs. Crampton and Wollaston, the engineers of the Submarine Telegraph

Company.

The cable, which was manufactured by Newall &

Co. in three weeks, measured originally 24 miles in length. Owing to the

manner in which it was laid down this was found insufficient to extend

from coast to coast, although the direct distance was only 21 miles. It

was therefore found necessary to manufacture an additional mile of cable,

which, being spliced on to the part laid, the whole was completed, and

the electric communication between Dover and Calais definitively established

on the 17th October, 1851.

The cost of the cable itself was £9,000, being

at the rate of £360 per mile. The total cost for cable and stations

at Dover and Calais was £15,000.

(information from The Electric Telegraph

Popularized by Dionysius Lardner)

The galvanised iron armouring wire for the 1851 cable was supplied by Richard Johnson Brothers of Manchester, later Richard Johnson & Nephew.

See also the Submarine Telegraph Company page.

The Illustrated London News, in its issue of 27 September 1851, described the manufacture of the cable and its loading on to the ship which would lay it, HMS Blazer. The core of the cable (four copper wires insulated with gutta percha) was made by the Gutta Percha Company of 18 Wharf Road, London, adjacent to the Regent’s Canal in a building which still stands today, and the armouring was added by Newall & Company at the works of the Submarine Telegraph Company in Wapping.

THE SUBMARINE ELECTRIC TELEGRAPH.

The Company for the execution of this great scientific labour have resumed their operations—it is hoped, to be rewarded by complete and permanent success.

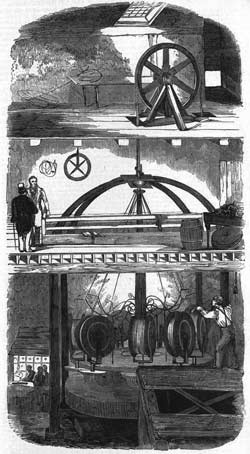

Section of the manufactory, showing the progress of the rope from the ground-floor to the wheel in the second storey.

|

The progress of these operations will hereafter be detailed; our object in this place being to describe, in its several stages, the manufacture of the great submarine telegraph rope, or cable, by means of which England and France are hereafter to possess instant intercommunication.

This stupendous work affords another instance, among many of the present day, in which the rapidity of execution borders on the marvellous; for, though the telegraph-rope be not less than twenty-four miles in length, it has been completed in the short space of three weeks No manual labour could effect such an undertaking scarcely in as many years; and any one who has had the opportunity of examining the machines employed, will find how much is due to the intelligence and exertions of George Fenwick, as engineer of the Seaham Harbour Ironworks, in Durham. The great machine represented in our Illustration was invented and constructed by him in ten days; but this is less wonderful than is its originality, its beautiful simplicity, and the clock-like precision of its working. The object for which it has been made is to obviate, as far as possible, any danger to the copper; and it certainly has produced a covering for the little news-transmitting wires, tending very strongly to baffle any attempts of wondering fishermen to cut it through, such as was the fate of the last telegraph between England and France. This, it will be recollected, was simply a copper wire, enclosed in a covering of gutta percha, and its fate was soon sealed.

Winding the iron wire on the bobbin |

At the suggestion of Mr. Wollaston (of the firm of Crampton and Wollaston, engineers to the company), the Gutta Percha Company, at their works, enclosed four wires, in all ninety-six miles in length, in a double casing of gutta percha. These, then, by means of a machine, were bound round in yarn steeped in a solution of tar, tallow, &c., which form the centre, or heart, of the rope. In this state it is sent through the iron tube of the great machine, which is surrounded by bobbins, whereon is wound as evenly as possible the iron wire which is to form the outer covering.

1. First layer of gutta percha over the wire.

2. Second, layer of gutta perch:, enclosing Fig. 1.

3. Section of Fig. 2.

4. Wires bound in yarn steeped in solution.

5. Galvanised iron wire.

6. Complete rope bound with galvanized iron wire. |

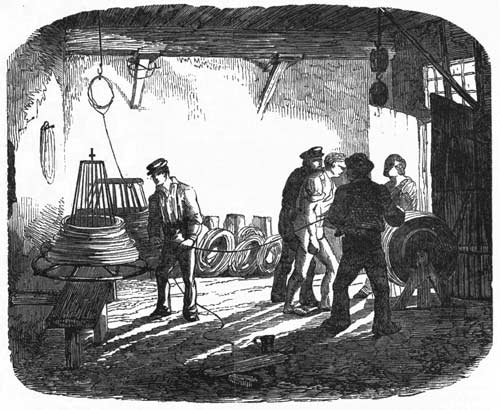

The winding of this wire, as represented in the Engraving, required great care to ensure its regularity when being transmitted from the bobbins through the laying (perforated) plate seen at the top of the tube, as it is in order to obtain a firm and even coil over the heart, or centre, that this machine has been invented. If, in the course of twisting, any of these iron wires snap, it is immediately welded together, then immersed in a zinc bath to prevent rust, and the process is again continued. After being thus cased in twisted iron wires, it passes over the centre sheave (a wheel on the second story of the works), thence over a whelp-wheel, and is conveyed out at the door to the coil in the yard, as represented in the View.

The submarine telegraph rope complete |

The steam-engine by which this machine is worked makes 60 revolutions per minute, driving the machine at the rate of 18 revolutions per minute, and drawing off 11 inches of rope in one revolution.

The labour to produce this telegraph has been ceaseless—day and night incessantly has the mighty coil been gathering its miles of length, to be conveyed on board the Blazer, the Government steam-ship, to proceed with it across the Channel.

We are happy to learn that Government holds out every aid and encouragement to the enterprising men who have undertaken to complete permanently what but a very few years since was deemed insanity or, at all events, not quite within the bounds of the possible.

The rope has been made by Messrs. Newall and Co., at the works of Mr. E. Weatherley, 39, High-street, Wapping.

To recapitulate, the rope is 24 miles long, and consists of four copper wires, through which the electric currents will pass, insulated by coverings of gutta percha: these are formed into a strand, and served or bound round with spun yarn, forming a core or centre, round which are laid ten iron galvanised wires of 5-16ths of an inch diameter, each welded into one length of 24½ miles, and weighing about 15 tons.

The rope weighs altogether about 180 tons; it forms a coil of 30 feet diameter outside, 15 feet inside, and five feet high, and has been made in the short space of 20 days.

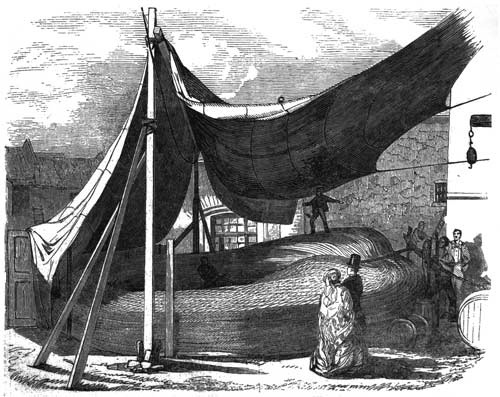

SHIPPING THE GREAT CABLE TELEGRAPH.

On Monday morning, at six o'clock, the interesting process of shipping, for deportation to its destination at Dover, the twenty-four miles of electric telegraph cable was commenced on the river-side premises of Messrs. Blyth and Co., at Wapping. The Blazer, an old war-steamer, of from 600 to 700 tons burden, commanded by Captain Bullock, was placed by the Admiralty at the disposal of the promoters, having been completely dismantled for that purpose. Her funnel, masts, and upper gear were removed, her boilers taken out. and, lying “high and dry” above tide, she presented nothing but a “sheer hulk.” The transfer of the great mass of cable out of the yard on to the vessel, though a very laborious business, was accomplished very cleverly. This was done by passing it over an elevated revolving wheel, above the coil, and thence to another wheel, some 7 feet in diameter, on to a stage some fifty feet high, overlooking the High-street, and thence through a wooden trough, across the street, on to the wharf on the opposite side, so as not to interfere with the traffic of the thoroughfares. Here it was again hauled with seaman-like celerity from off the wharf on to the prow of the vessel, over what are termed “chocks” and supporting poles, at the rate of about a mile an hour, and then stowed away in a continuous coil down the hatchways into the hold. This process was rendered the more laborious in consequence of the clammy covering of tar, which, owing to the nature of the process employed in the manufacture, still adhered to the cable, and it was not completed until Wednesday morning about ten o'clock, when, after working throughout the night, the entire coil of telegraphic tackle was safely deposited by the workmen on board the Blazer, which was immediately taken in tow by two steam tugs, and thus proceeded to Dover.

In its issue of September 9th, 1852, The Leisure Hour had this report of the manufacture of the 1851 cable:

“Will you allow me, sir, to see the Marine Electrical Telegraph?” asked an elderly lady, a short time ago, as she entered the office of the company; expecting, doubtless, that the gentleman she addressed would open a door, invite her to follow him, and then disclose the mighty wonder, just as if it was as visible as an elephant in the Zoological Gardens, or occasionally went into, and came up from the water, just like its far-famed Hippopotamus.

It is, indeed, no easy thing to take up our standing on the sea-shore, and to realize distinctly and firmly the absolute fact. Mighty ships, are wafted onwards as the wind fills their sails, or steam, a scarcely less wondrous agent, plies the paddle-wheel or the screw, ploughing the waves on the ocean's surface; troops of fishes sport and frisk and flounder in mid-water, each of them happy in its own existence; while sunk amidst the sea-weed, the shells and the pebbles of the bed of the deep, is that iron cable, along the meanderings of which words and thoughts are silently chasing one another, hurried on the lightning's wings, from island to continent, and back again from continent to island.

That we may form a correct idea of this newly devised agency for international communication, we must first visit the works of the Submarine Telegraph Company, situated at Wapping, where, notwithstanding the unsurpassable aggregate of tar, smoke, and steam, many highly distinguished persons have felt there existed a powerful attraction. Reaching the High-street, and entering the factory, the eye immediately rests on two well-constructed machines, each about twenty feet high and fifteen in circumference, a large iron framework, in fact, in the form of a cupola, with a shaft or cylinder in the centre, worked by a steam-engine of five-horse power. A bell rings, and immediately the workmen from the establishment of Messrs. Newall of Gateshead, gather round one of these machines for the first process. And now there issues from it a layer composed of four electric copper wires, known as the sixteen-wire gauge, each incased in a covering of gutta percha, of a quarter of an inch diameter; and these, aided by the manipulators, are twisted and plaited in spiral convolutions, like an ordinary rope or cable. The next superincumbent coil to this consists of hempen yarn, previously saturated in a reservoir of prepared pitch and tallow, and this, in its turn, is tightly twisted and compressed, impermeably, over the gutta percha, with its inclosed copper wires. This, too, is overlaid with a series of hempen yarns, five or six in number, and about an inch in diameter, saturated in the pitch and tallow, with the design of “worming,” as it is called, the gutta percha, acting in fact, as a protective covering; while over this is drawn a coat of mail of galvanized wire.

Such, then, is the first process: the second consists in hauling off the wire so far completed, and passing it, in another compartment of the factory, to another wire-rope machine, where the cord is completed, covered over with ten galvanized iron wires, each wire being about the thickness of a common lead pencil, and known as No. 1, galvanized iron wire-gauge. This sheathing is to defend the inner layers from the action of the sea, and the weight is considered sufficient to sink the cable. The appearance of the cable thus completely incased in a coat of galvanized iron, and divested of tar and dirt, is quite silvery. The coil when completed is drawn off from the machine, and draughted out by the men, just as sailors haul rope, into the factory yard, where it will remain, for a time, rolled up into a circle some five feet in height, and twenty feet in circumference, representing a dead, weight of two hundred tons. It is tested by firing a fusee through it, from one of the batteries which are in the building. In this way the whole of the numerous miles of communication, represented by the wires of the Submarine Telegraph was prepared, tested, and found complete, by Mr. Wollaston, in the Regent's Canal.

In its issue of November 1851, the Engineer and Machinist described the laying of the cable:

THE SUBMARINE TELEGRAPH.

Some very loose and inaccurate statements having appeared in several journals respecting the submarine telegraph, it is desirable that a few facts should be brought prominently before the public, to enable them to form a correct opinion of the present condition and future prospects of an enterprise of such importance to both the commercial and scientific world.

On the 19th of July [1851] Mr. Crampton undertook to construct and lay down a cable containing four electric wires, each insulated in two coatings of gutta percha, and the whole protected by ten strands of galvanized iron wire, on or before the 30th of September. The electric wires, covered with gutta percha, in length 100 miles, were turned out by Mr. Statham, at the works of the Gutta Percha Company, and nothing can be more perfect than the manner in which that order was executed. The wire covering was ordered from Messrs Wilkins and Weatherley, but unfortunately, a dispute respecting the patent for making wire ropes occurred between that firm and Messrs. Newall, which seriously delayed the progress of the work, as an injunction was served by the latter to prevent Messrs. Wilkins and Co. from proceeding with the order. This was eventually compromised, and the rope was made conjointly by the workmen of the two firms on the premises of Messrs. Wilkins and Weatherley, at Wapping.

The very hurried manner in which (from this unforseen delay) the work had to be accomplished, prevented that close attention that ought to have been given to any fracture, however small, of the wire, and in consequence the outer casing, though of great strength and solidity, was not made with the same exquisite nicety and care that had been bestowed on the core of the cable.

On Wednesday, the 24th, the coiling of the cable in the hold of the Blazer was completed, and at mid-day she was towed off by two steam-tugs, and at 3 o’clock on Thursday morning anchored off the South Foreland. About 6 o’clock the engineers and gentlemen interested in the experiment were brought off to the South Foreland in Her Majesty’s steamer Fearless, Captain Bullock, and in half an hour’s time the telegraph rope was landed, and safely secured at a considerable elevation above high-water-mark, at the South Foreland, immediately under the upper lighthouse, and at the bottom of a shaft that descends perpendicularly from near the lighthouse to a level with the beach. Through this shaft it is proposed to carry the electric wires, and then from the summit of the cliff to run them under ground into Dover.

The point fixed for the debarcation on the French coast was Sangatte, a small village, situated about three-and-a-half miles by the coast from Calais, and about five by the public road. The distance from Sangatte to the South Foreland is 21 miles, and the length of rope on board the Blazer was 24.

Shortly after 7 o’clock the fastenings at the end of the cable at the Foreland were completed, and the Fearless started to point out the exact course to be followed by the Blazer, which was towed by two tugs, one alongside and the other ahead of her. A third tug belonging to the government was also in attendance.

The arrangements for paying out the cable consisted simply of a bar, fixed transversely above the hold, over which the rope was drawn as it was uncoiled from below, and a series of breaks acting by levers fitted to the deck, in order to arrest the passage of the rope in the case of too rapid a delivery. On reaching the stem the cable passed overboard through a "chock" of a semicircular shape, lined with iron. On starting, the steam-tugs proceeded at much too rapid a pace (from four to five knots an hour), and consequently one of the fractured wires (before alluded to) caught in the friction blocks, and before the way of the vessel could be checked, one strand of the iron wire was, for a length of about 18 yards, stripped from the cable. The steam-tug towing ahead was then ordered alongside, when the speed could be better regulated, and the rate was reduced to about one and a-half to two knots an hour. About six miles from shore it was determined to test the wires, but from a misapprehension of instructions the telegraph instruments at the South Foreland were not joined up with those on board the Blazer. A steam-tug, with one of the engineers and directors on board, immediately returned to the Foreland, when communication was made by telegraph, and fusees fired from the vessel to the shore, and from the shore to the Blazer.

At about mid-channel, in the midst of a heavy sea, and a strong wind from the S.W., an accident occurred, but for which the enterprise would have been carried out with the most perfect success; this was the snapping of the tow-rope (an eight-inch cable) and the consequent drifting of the Blazer from her appointed course to the length of a mile and a-half. Notwithstanding the delay caused by this untoward incident, the Blazer arrived off Sangatte at about six o’clock. The evening was, however, too far advanced, and the weather too stormy, to attempt a landing; and, after embarking most of her passengers on board one of the steamers that ran into Calais, she was anchored for the night about two miles from the shore.

On Friday the wind blew a strong gale from the westward, which rendered all near approach to the shore impracticable; but the Blazer was towed to within a mile of the beach, when it being considered dangerous to leave her at anchor, the remainder of the rope was made fast to a buoy and hove overboard. The steam-tugs then returned with the Blazer to England.

On Saturday the weather continued unfavourable, but Captain Bullock proceeded with the Fearless to the buoy off Sangatte, and having hauled up the end of the rope he towed it some hundred yards nearer the shore, and then again moored it.

On Sunday the wind shifted more to the southward, and moderated. Accordingly, the engineers and managers of the Gutta Percha Company took on board the Fearless a large coil of gutta percha roping, and, after hauling up the end of the telegraph cables, the first wires were carefully attached, and at half-past five in the afternoon a boat landed them on the beach at Sangatte. The moment chosen for landing was low water, and the coil of gutta percha ropes was immediately buried in the beach by a gang of men in attendance up to low water mark, and even to a short distance beyond it. Thence to where the cable was moored did not much exceed a quarter of a mile.

The telegraphs were instantly to the submarine wires, and all the instruments responded to the batteries from the opposite shore. At 6 o’clock messages were printed at Sangatte from the South Foreland, specimens of which Captain Bullock took over to Dover the same evening for the Queen and the Duke of Wellington.

On Monday morning the wires at Sangatte were joined to those already laid down to Calais; and two of the instruments used by the French government having been sent to the South Foreland, Paris was placed in immediate communication with the English court. Experiments were then tried by firing a cannon on the ramparts of Calais by means of electricity passed along the sub-marine wires from England, all of which were perfectly successful.

On Monday evening, at 6 o’clock, the Mayor and corporation entertained the gentlemen connected with the sub-marine telegraph at dinner at the Hotel de Ville, and on Tuesday morning the French man-of-war steamer Ariel, Captain Arpin, took them back to England.

On Tuesday afternoon Mr. Wollaston, civil engineer, accompanied by Sir James Carmichael and Dr. de Hamel, of the Academy of Science of St. Petersburgh, proceeded to the South Foreland, where, in the presence of the other gentlemen, Mr. Wollaston tested the sub-marine wires with a galvanometer, and pronounced their insulation to be perfect.

The telegraphs used on this occasion have been those of the French government, invented by M. Foy, Henley’s magnetic, Reid’s double needle, and Brett’s printing telegraph. In spite of much knocking about and rough work, both on board and on shore, the instruments have all worked admirably The gentlemen connected with the Sub-marine Telegraph Company, who gave their aid on this occasion, were Mr. Crampton, C.E., Mr. Wollaston C.E., Mr. Statham, manager of the Gutta Percha Company, Mr. Branton, his assistant, Mr. Jacob Brett, to whom the concession was granted by the French government for establishing the telegraph, Mr. John Brett, and Sir James Carmichael, Bart, directors.

M. Alphonse Foy, the director of telegraphs in France, and Professor Jacobi, were also present during the first part, and Dr. de Hamel, of St Petersburgh, during the latter part of the work.

Messrs. Reid and Henley attended in charge of their respective telegraphic machines.

Much has been said of the foolhardiness of starting during the prevalence of the equinoctial gales and the period of the strongest tides to lay down the sub-marine cable. This, however, was inevitable as the company were under engagement to the French government to establish a communication between the two coasts by the 1st of October, and as the cable was not shipped on board the Blazer until the 24th of September, there was little time to carry out so novel and so difficult an undertaking.

The communication is now made, and when the short distance of gutta percha roping at Sangatte is replaced by a properly protected cable, it will, we trust, be as permanent as it is already proved to be perfect.

The operation of the cable proved very successful, both technically and financially. In his 1853 book "The Electro-Magnetic Telegraph," Laurence Turnbull wrote:

The Submarine Telegraph Company, between France and England, has declared a dividend of 2½ per cent, on the operations of the first six months. The capital account shows a receipt of £100,000 on so many shares of £1 each, and an expenditure as follows:

By amount paid to the concessionaires and entrepreneurs, under the terms of Article 9 of the Acte de Société, cost of experimental wire, cost of existing cable, and amount paid on account of the wires in connection with the submarine cable at Dover, £70,233 7s 3d; candon money in the hands of the French Government, £2,000; amount paid for office furniture, £216 12 9. Total, £72,450. The balance of £27,550 is composed of 2,550 value of shares held in the hands of the Company, and 25,000 shares unallotted.

The revenue account shows that £3,546 8 5 have been received for messages transmitted from Nov. 30, 1851, to June 30, 1852: The expenses at the London, Dover, Calais and Paris stations, including printing, stationery, postage, and other incidental charges, were £238 12 9; salaries and wages, £805 17 1; rent and taxes (London, Paris and Dover), £170 6 10; directors’ allowance (half a year under Article 10 of the Act of Society), £3,000. Total, £1,514 16 8, giving a net profit of £2,031 11 9.

Since Nov. 15, 1851, the Company has transmitted 9,045 messages from London to Calais, for which it has received £6,889 13 9. Two thousand seven hundred and ninety-four of these pounds have been paid to the South-eastern Railway. The Submarine Telegraph Company is already receiving nearly £450 a week for messages, or £22,000 a year, which is 15½ per cent. on the capital.

London, May, 1853.

|