As the story of S.T.C. unfolds nothing is more remarkable than the way in which the Company has been given a ringside view of history—in the writing of which it has, indeed, taken an active part. Side by side with the “ceremonials,” from the Diamond Jubilee to the Queen's Coronation, there runs the parallel history of technique. Over three quarters of a century S.T.C. has become increasingly familiar with both kinds. The thermionic valve, the loading coil, audio repeaters, V,F, carrier telegraphy, carrier telephony, coaxial cable, the S.H.F. link—with all these important technical developments S.T.C. had been closely identified, and it was particularly appropriate that the Company should play its part in the completion of one of the great engineering feats of our time: the transatlantic telephone cable system.

Over a period of thirty years until 1956, development in the realm of submarine communications was confined largely to the provision of telegraph services or telephone facilities over relatively short distances. The main factor limiting progress in submarine cable systems was the problem of amplifying telephone signals with repeaters at regular intervals to maintain the signals at intelligible strength.

In 1951 S.T.C. provided the submerged repeaters for the cable link between Leeuwarden, in the Netherlands, and Copenhagen, capital of Denmark. This project, one of the largest of its kind undertaken in Europe since the end of the war, proved of great value in improving communications between Scandinavia and the other countries of Western Europe.

Three years later the Company designed and manufactured the submerged repeaters and associated terminal equipment for the North Sea cable laid between Aberdeen and Bergen in Norway, a distance of 300 nautical miles. Until the laying of the first transatlantic cable in 1956, this was one of the longest submarine telephone cables in the world.

These achievements led to the Company being entrusted with the order for the provision of the submerged telephone repeaters for the important Nova Scotia-Newfoundland section of the transatlantic cable.

This section covers a distance of about 330 nautical miles and employs a single coaxial cable, as compared with the two cables (each serving one direction of transmission) in use over the major part of the route. In addition to the thirty-six trans-ocean circuits, this section also carries twenty-four telephone channels for traffic between Newfoundland and the mainland. Altogether sixteen two-way submerged telephone repeaters were provided, two of them in the cable where it made the short overland crossing between Clarenville and Terenceville in Newfoundland, and the remainder laid in varying depths of water between Terenceville and Sydney Mines, Nova Scotia.

Once laid, the cost of replacing a submerged repeater is not an economic proposition unless it gives an uninterrupted service over a period of many years. To guarantee this calls for wide experience in the design, manufacture, and selection of components, and in their use in circuit arrangements which have shown their life to be exceptionally long.

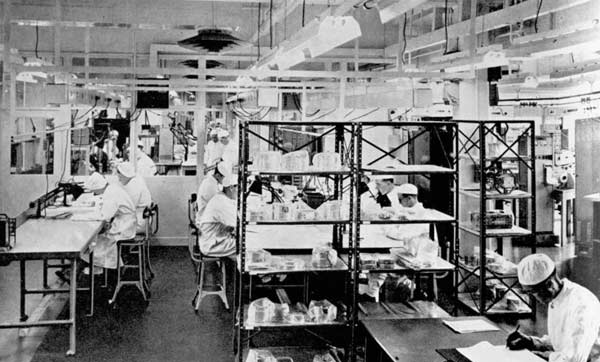

S.T.C.'s concentration on obtaining the very highest degree of efficiency and reliability out of every component led the Company to take the most elaborate precautions during manufacture of the transatlantic repeaters. At North Woolwich a special manufacturing unit was created which was concerned solely with submerged repeater manufacture, There, in filtered, dust-free, conditioned air, carefully chosen and trained operators in special clothing did their work, fully alive to their responsibilities and the consequences of an error, however small. Raw material to rigid specifications and drawn from carefully specified sources came into this unit only after having been meticulously checked before acceptance,

The nylon clothing of the operators, the insistence on absolute hygiene, the almost clinical appearance of the shops concerned, led inevitably to the unit becoming known as “The Dairy” - but it was only by this attention to detail that the ideal could he achieved. What the Company was striving for, after all, was perfection. Altogether twenty-one repeaters were manufactured at North Woolwich — five of them spares. Every repeater contains some 300 components, including six valves and comprising several thousand piece-parts, every one of which was individually treated and subjected to the most rigorous inspection.

“The Dairy.” So-called because of the almost clinical cleanliness demanded, this special shop was established in the North Woolwich factory for the manufacture and assembly of the submerged repeaters for the Newfoundland-Nova Scotia section of the transatlantic cable. |

Inspection had to coincide with all the manufacturing processes so as to guarantee reliability to the nth degree. Individual components were rigorously checked and inspected at each process. Sample components from each batch were over-stressed or tested to destruction so that the engineers could assess the quality of the product. Similar precautions were taken in sub-assembly and assembly stages, and the completed repeater was subjected to detailed performance tests before being sealed in its inner case.

The cable and its two-way repeaters was laid across the Cabot Strait in depths of water of up to 250 fathoms by H.M.T.S. Monarch, which had to be specially fitted to handle the two-way repeaters. The repeaters were despatched at pre-arranged intervals from S.T.C's Woolwich factory to the Monarch, to enable them to be spliced into the cable as loading proceeded.

From Clarenville the single cable follows a short route overland to Terenceville on the bleak coast at the head of Fortune Bay. Two of the sixteen submerged repeaters were laid in pits by the sides of lakes between these two points. The Terenceville station is a small unattended building that serves to shelter a cable terminating box at the point where the cable enters the sea, In Sydney Mines, which is one of five mining towns clustered round Sydney, Nova Scotia's second largest town, the submarine cable is terminated in equipment similar to that in Clarenville.

The cable was completed in July 1956, almost a century after the first telegraph cable had linked England and America. With it, telephone communication between old world and new was made complete and a new chapter had been written in history.

Shortly after this success, the Company obtained a contract for two-way repeaters to be laid over a similar stretch of cable (Nova Scotia-Newfoundland) in a new transatlantic cable project for the French Government and the American Telephone and Telegraph Company.

In March 1958 came news of a third and even more important order, once again in Atlantic waters.

The operating success of the first cable had more than fulfilled the hopes entertained for it. A new cable was now projected — CANTAT (Canadian Transatlantic Telephone Cable), to be owned jointly by the Canadian Overseas Telecommunication Corporation and Cable and Wireless Ltd.

The new cable would provide at least sixty telephone circuits — any one of which would, if required, supply upwards of forty additional telegraph channels. Transatlantic telephony by cable was in hot demand.

For this cable the Company was to supply all the submerged repeaters — about 100 altogether — over the entire 2,500 miles of ocean.

Cantat is being designed to meet the estimated telephone and telegraph requirements between Canada and Britain for twenty years ahead, and is scheduled for completion in 1961. The Company can take a special pride in the fact that it has been honoured with such an important role in this ambitious project — the first Commonwealth transatlantic cable.

As S.T.C. prepared to celebrate its seventy-fifth anniversary its engineers were completing yet another project that held out new and exciting prospects. The Anglo-Belgian Submarine Telephone Cable Scheme, as it is called, was being pressed to completion for the opening of the 1958 Brussels Universal and International Exhibition in April of that year. The Anglo-Belgian project marked the first occasion in the development of submarine cable systems that one organization had been entrusted with the manufacture of the undersea cable, the submerged repeaters, and the supply and installation of the land-based terminal equipment and cable. S.T.C. and its Belgian associate, the Bell Telephone Manufacturing Company Ltd., of Antwerp, were awarded the contract for this important submarine link.

The link is designed to give 120 two-way telephone channels over a single submarine cable, and the cable being used consists of a polythene-insulated coaxial cable comprising an inner copper conductor made up of a strand of seven wires insulated from the outer conductor by a solid dielectric of polythene. The outer conductor consists of a layer of six copper tapes plus one copper binding tape. The cable has a serving of tarred jute and is armoured with galvanized steel wires. Submarine length is 55 nautical miles.

At the British end the link's land terminal is located at the G.P.O. Repeater Station at Canterbury, where it is fed into the national telephone network, From there a 16-mile cable runs to the Kent coast, where the submarine section begins. The submarine cable crosses the Belgian coast at Middelwerke and is linked by another land cable, five miles long, to the Belgian terminal at Ostend Repeater Station. The cable contains three submerged repeaters similar to those being used on the Newfoundland-Nova Scotia section of the transatlantic telephone link. Repeaters and land cable for the project were made at North Woolwich, and the submarine cable at S.T.C.’s Southampton factory.

TAT-1 remained in service until 1978 without a single failure, and was withdrawn from service only because many higher-capacity cables had by then been installed across the Atlantic.

In 2006 the engineering achievement of TAT-1 was commemorated with the installation of a plaque at the Transatlantic Cable Monument site in Clarenville, Newfoundland, the site of the Canadian landing of the cable. The photograph below, from Tom Wills of AT&T, shows the plaque before it was sent to Newfoundland.